Solar Hydronics Automation System

Summer 2013

See the full research paper.

Abstract

This study involved engineering an automation and communications

network to control heat flow in a novel solar hydronics system in a

Roseville, Minnesota home. The goal of this system was to

effectively store enough of the sun's heat during the summer months

to heat the home throughout the winter. We installed a Modbus

network—the industry standard for RS485 communication—that consists

of a master Arduino Mega and five slave Arduino Micro modules. We

created software in C/C++ to run 100 temperature sensors, one

humidity sensor, and eleven water circulators that direct heat flow

to heat-storage components. A unique aspect of the software

developed in this study is that it adjusts to time of day, outside

temperatures, dew point, humidity, and time of year in order to

determine the most effective allocation of the available heat. Final

testing of the communications network showed 100% success rate.

Because the network can be easily modified or expanded, it is easily

applicable to any solar-powered hydronics system.

Introduction

In hydronics systems, water flows through an extensive system of

tubing to either heat or cool a residence by radiating or absorbing

heat. The house in Roseville is an example of newly developing

hydronics systems that use solar collectors as their source of heat.

Before our work, distribution of water in the hydronics system of

the home had to be controlled manually by opening and closing pumps

as needed. The goal of our work was to wire and program a

communications network to automate the hydronics system to respond

to seasonal temperatures, time of day, dew points, humidity, and

time of year.

In order to calculate the most effective heat allocation, the

automation network must know input and output water temperatures

of each component in the hydronics system. For this home, these

components include:

-

Four banks of Solar Skies SS40 4x10 solar collectors — the source

of heat for the entire system.

-

Three long-term storage sand beds — stores excess heat in the

summer and sources heat during the winter.

-

Two short-term water storage tanks — stores excess heat during the

daytime, and returns that heat to the system at night.

-

Three zones of in-floor hydronics tubing — Radiates heat into the

home. Also equipped with a cooling loop for absorbing heat in the

summer.

-

Domestic hot water heat exchanger — transfers heat to potable

water for showering or other uses.

Since all of these components are sparsely distributed throughout

the house, we determined that a master/slave communication network

would be the best way to read temperature data from all of the

them.

Prototype 1: I2C

We determined that the most important aspect of this system was

first to reliably read data from the temperature sensors. We created

our first prototype using I2C with the goal of demonstrating

multi-controller communication of temperature data.

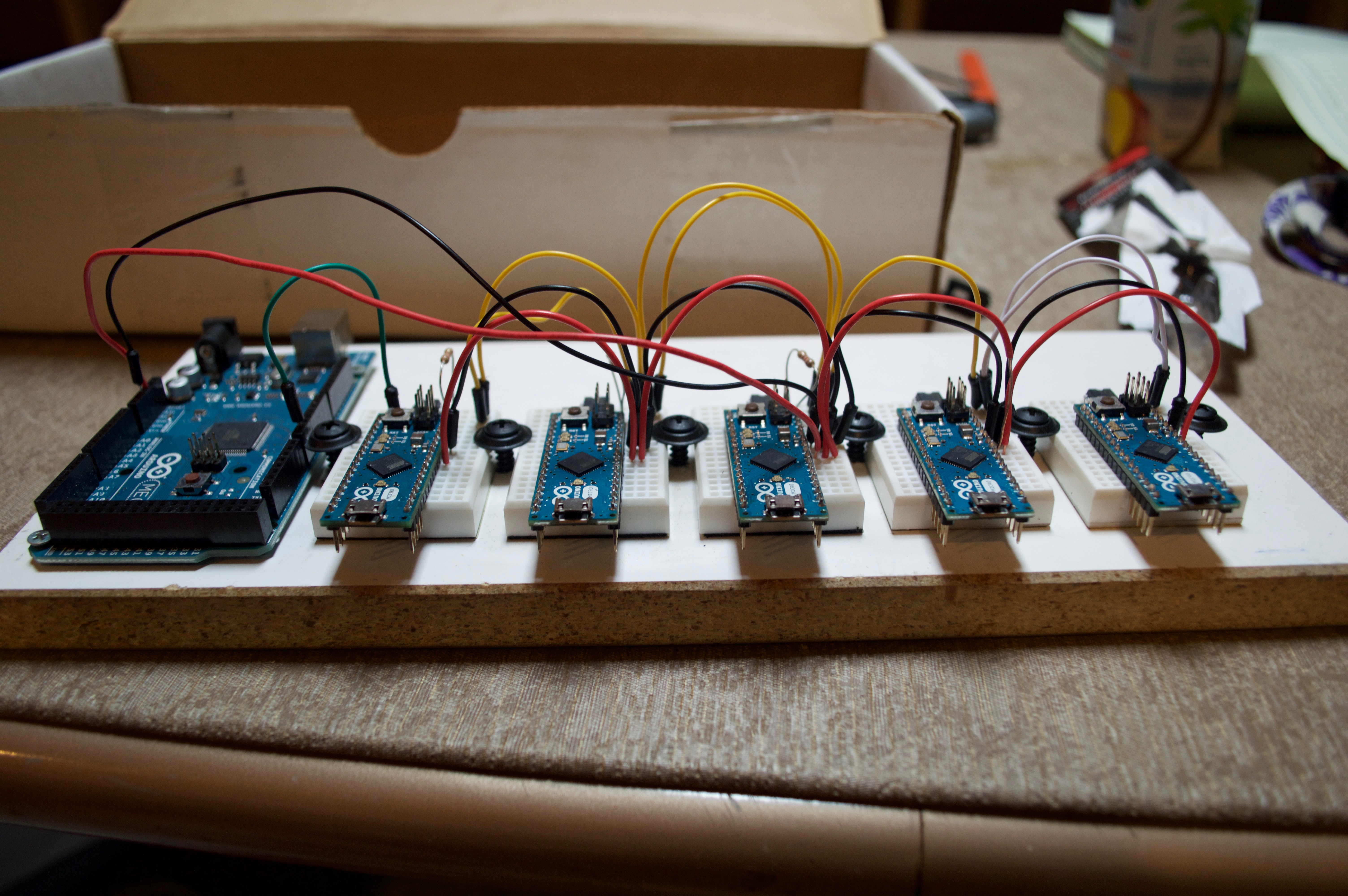

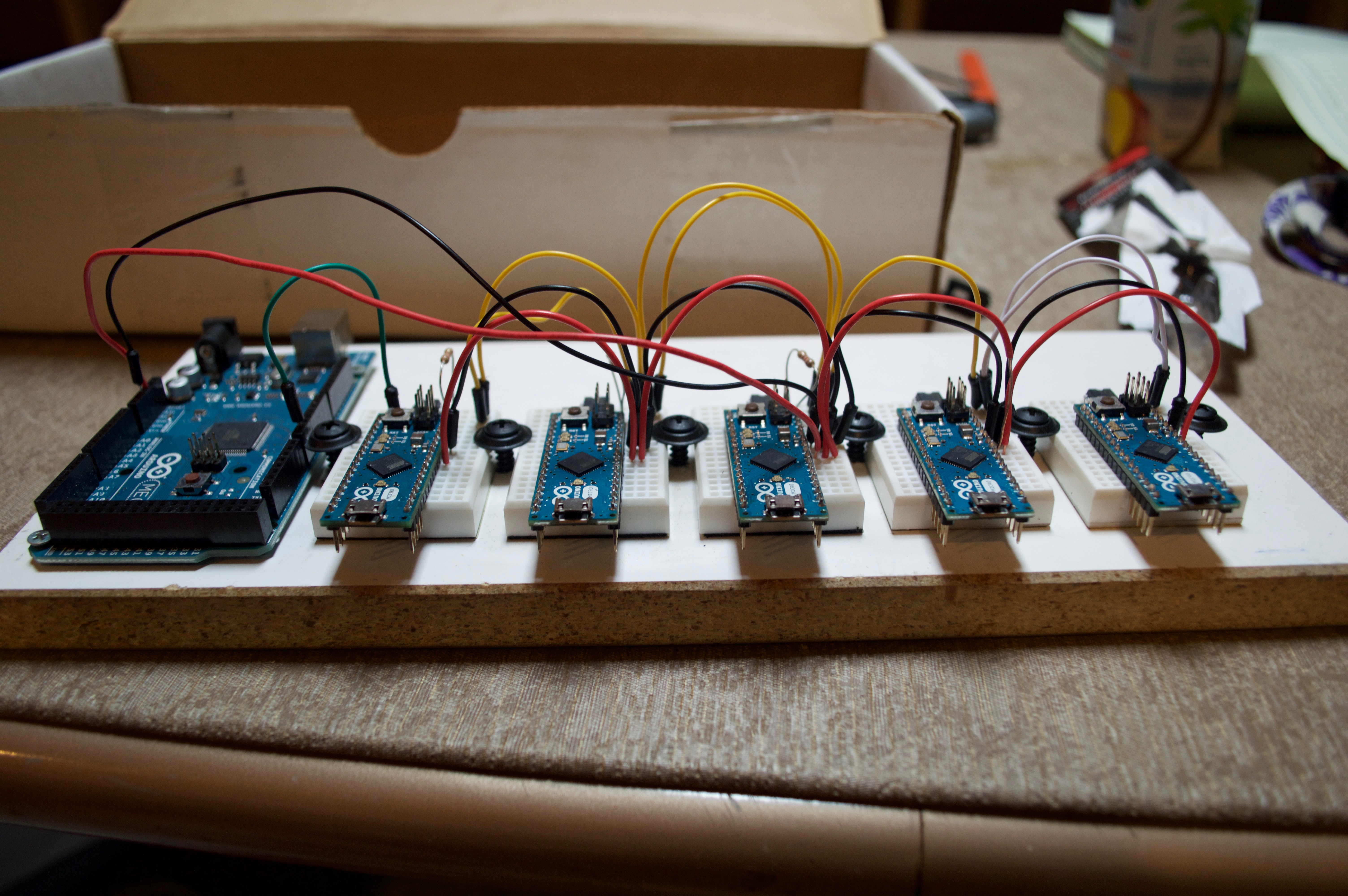

Our first prototype network. All of the smaller microcontrollers

have their own temperature and humidity sensors and are

communicating their data to the master controller.

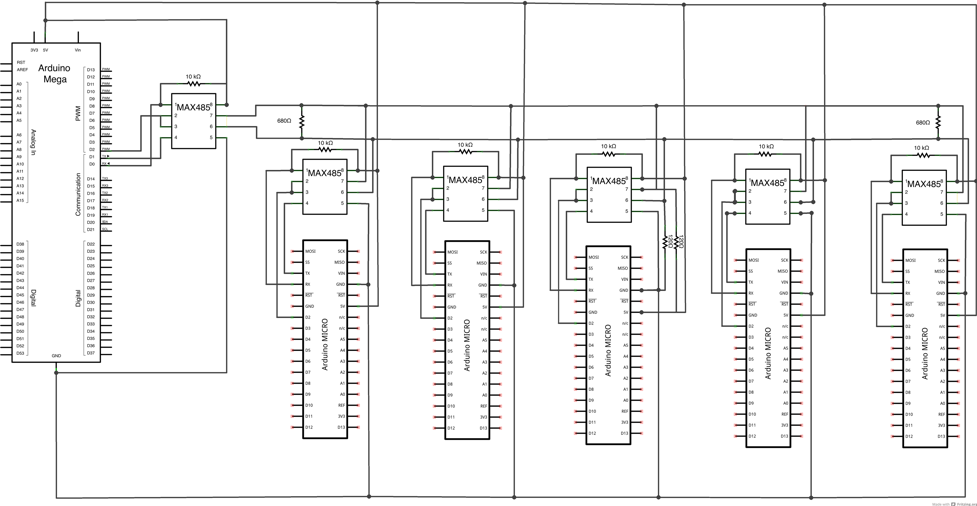

Prototype 2: Modbus

Upon further testing, we learned that an I2C network is not reliable

over the long cable-runs we needed for physical placement in the

home. For this reason, we decided to update our network using the

Modbus protocol. We used the MAX485 integrated circuit to accomplish

full-duplex communication between the microcontrollers. They could

then send all temperature values to the master controller and

receive their output instructions without any lost data packets.

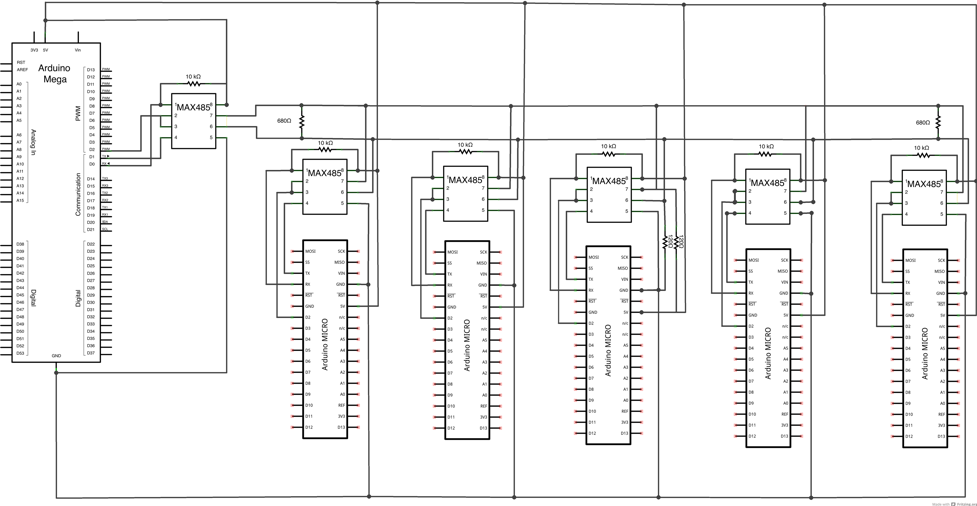

A schematic of the Modbus network used in this project.

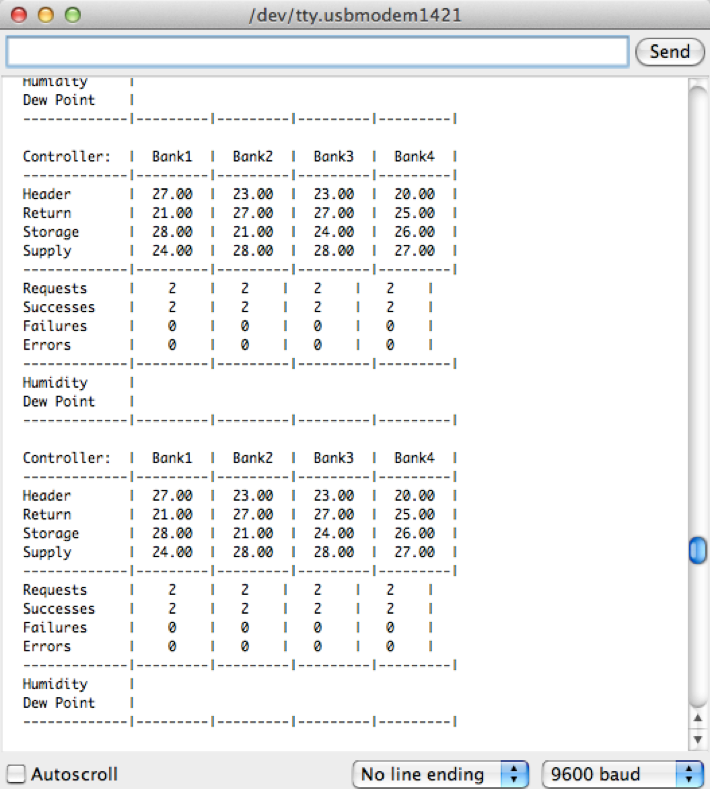

Results

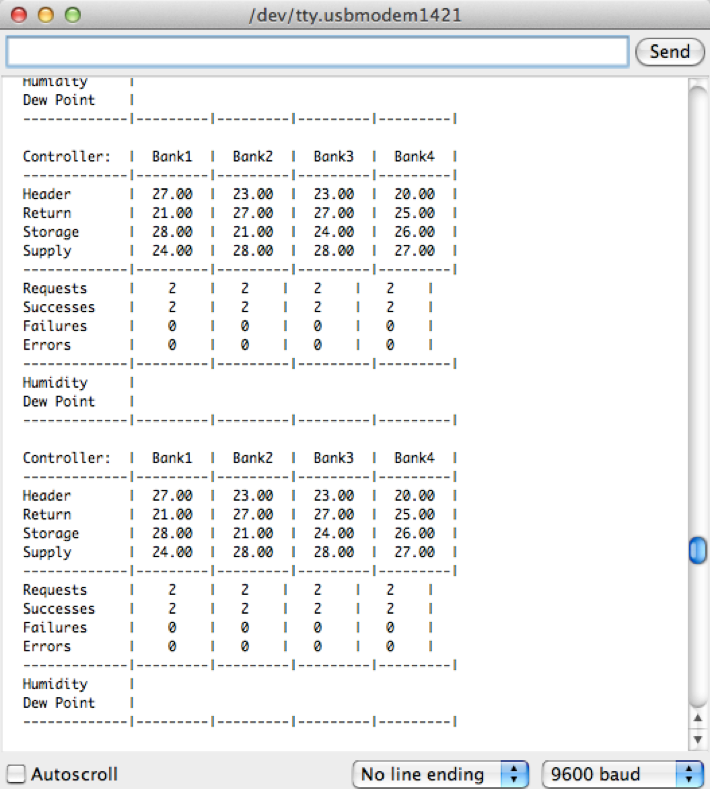

The console output of the Arduino Mega shows that all temperature

values from the slave controllers were received successfully.

After out control system was installed in the house, operating

costs decreased by 75%. This is entirely due to increased storage

efficiencies, since the system sends the water to the storage

location where heat can be exchanged most efficiently.

Conclusion

Our technology uses an efficient hydronics system to heat a

Roseville, Minnesota home with zero greenhouse gas emissions. With

hot summers and freezing winters, a significant amount of heat

must be stored throughout the non-winter months. Our technology

logically decides whether to store heat in long-term storage or

short-term storage or distribute heat throughout the house. The

system can also be completely run off of low voltage DC power,

which is provided by solar panels and batteries. These power

sources will continue to run in the event of power outages.

A unique aspect of the software is that it adjusts to time of

day, outside temperatures, and time of year in order to make

logical decisions about where to distribute heated water from the

solar panels. For example, the program directs heat into sand beds

in the summer to store heat for winter. On the other hand, the

program responds to high indoor air temperature readings by

injecting cold water into the hydronic system water to cool the

house. By calculating approximate dew points, the program keeps

the colder water above the dew point to prevent condensation in

the house.